FFC/FPC Connector and Cable Compatibility Basics

Did you know that Molex manufactures both FFC/FPC connectors and the jumper cables that mate into them? In the electronics world, these two products are like peanut butter and jelly – many times sold and utilized together. Molex aims to support its customers in the best possible way by providing a complete interconnect solution.

Molex takes the guess work out of selecting the best mating connector and cable for your application. For starters, our FFC/FPC connector and cable teams work together to make sure that our specifications and tolerances align to ensure compatibility and reliability. If you see an FFC/FPC connector on DigiKey’s website, you can often find the mating Premo-Flex cable linked in the product information.

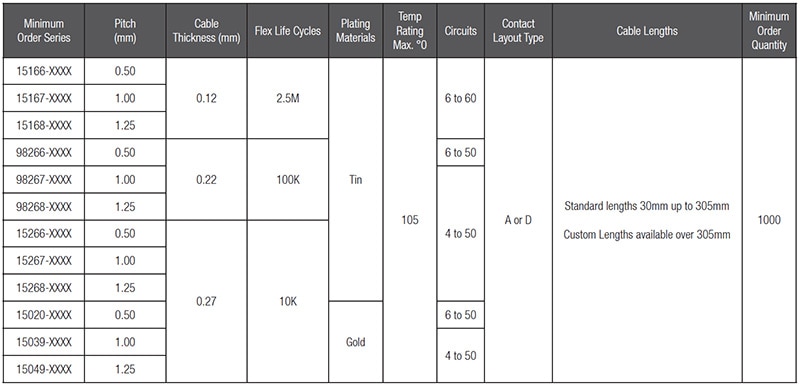

It is helpful to have an FFC/FPC connector selected before the mating Premo-Flex cable, because the connector will tell you a lot about the type of cable you need. Start with the easy specifications. If you have a connector with 30 circuits, you are going to need a cable with 30 circuits. If your connector contacts are spaced 0.50 mm apart, then your cable will need to have a pitch of 0.50 mm as well. Lastly, check the plating of your connector. Is it tin, gold, or another material? The plating of the connector and cable should always match to avoid quality risks.

Now that you know the circuit count, pitch, and plating, you will need to evaluate your application:

- You will need to determine what cable length is needed by measuring the distance between the two items you are trying to connect, such as two PCBs, a PCB and an LCD, or a number of components.

- Note whether you will need the exposed contacts on the same side or on opposite sides of the cable. We refer to these contact types as Type A (same side) and Type D (opposite sides).

- Consider the amount of motion the cable will endure within the application. If the cable will be installed in a static application, then you can likely utilize a slightly thicker cable that will withstand up to 10,000 flex life cycles. In contrast, if your cable will be flexed many times over the course of its life, such as in a robotic arm application, then you will likely need to utilize a Premo-Flex cable designed for 100,000 to 2.5 million flex cycles.

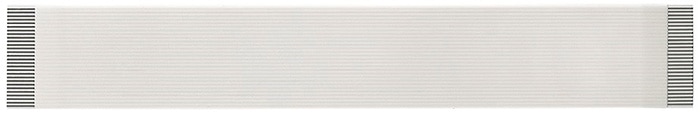

Type A cable with exposed contacts on the same side (Image source: Molex)

Type A cable with exposed contacts on the same side (Image source: Molex)

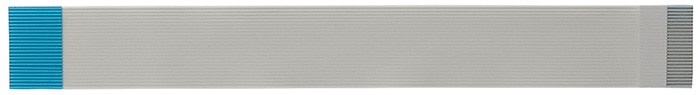

Type D cable with exposed contacts on opposite sides (Image source: Molex)

Type D cable with exposed contacts on opposite sides (Image source: Molex)

You should now have all the information you need to select the mating cable for your application. Additionally, Molex always recommends sampling a cable or two to try out in your application and to perform reliability testing. If you still have questions, do not hesitate to reach out to the DigiKey customer service team or to Molex directly. We can review your opportunity with you and recommend the best-suited standard solution or develop a custom version. Happy cable and connector matching!

(Image source: Molex)

(Image source: Molex)

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum