Use Hybrids To Bring the Benefits of Both Batteries and Supercapacitors to Power IoT Designs

Contributed By DigiKey's North American Editors

2021-03-24

Designers of products for applications ranging from small-scale Internet of Things (IoT) nodes, asset tracking and smart metering, to larger ones like equipment backup power and status reporting, increasingly require an independent source of rechargeable power. Typically, their choices have been limited to an electrochemical battery, usually based on lithium (Li) ion chemistry, or an electric double-layer capacitor (EDLC), often referred to as the supercapacitor or supercap. The problem is that whether used alone or in combination, each technology presents certain limitations, requiring developers to balance the capabilities and limitations of each against their design objectives.

Those objectives, particularly for low-power IoT and Industrial IoT (IIoT) applications, typically include reliability, long operating life, efficiency, energy density, and ease of use, leading to a simpler design and integration process, shorter development time, and lower project cost. While it’s perfectly feasible to use both Li-ion and EDLCs together to achieve these goals, designing and optimizing for both approaches can be a complex endeavor. An integrated approach may be more suitable.

This article discusses the requirements of IoT power designs and the technologies behind electrochemical batteries and EDLCs. It then introduces an alternative approach in the form of hybrid energy storage components that combine the attributes of batteries and EDLCs in a single package. The article will introduce example devices from Eaton — Electronics Division and discuss their characteristics and application.

IoT systems demand low power, long operating life

The last few years have seen tremendous growth in low-power, low-duty-cycle applications that can operate from relatively small power sources. Although the circuitry in these devices have active-mode operating currents ranging from milliamps to amps, these devices often feature extended operation in deep-sleep modes that typically require only microamps. The use in these devices of low-power, low-rate, low-duty-cycle wireless technologies such as LoRaWAN or Bluetooth low energy (BLE) also helps minimize power consumption.

For these operating conditions, designers have typically considered two energy storage technologies: some variant of the Li-ion battery or a supercapacitor. Each provides tradeoffs in energy capacity and density, lifetime cycles, terminal voltage, self-discharge, operating temperature range, performance at low and high discharge rates, and other factors.

Key differences in storage technologies

In brief, whether it is a primary (non-rechargeable) or a secondary (rechargeable) cell, a battery is based on electrochemical principles. A lithium-based battery contains a graphite anode and a metal-oxide cathode, with an interposed electrolyte that is usually liquid but can be solid in some implementations. The life of rechargeable cells is limited typically to several thousand charge/discharge cycles due to various forms of internal degradation.

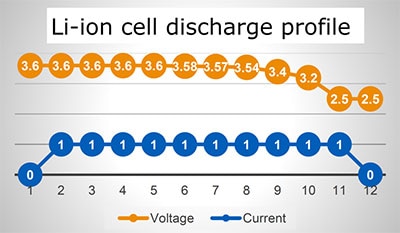

In addition, batteries require sophisticated cell and battery pack management to maximize operating life while preventing issues such as overcharging, thermal runaway, or other fault conditions that can result in degraded performance, cell destruction, or even fire. For designers, the relatively flat discharge profile of these batteries simplifies circuit implementation (Figure 1).

Figure 1: The discharge cycle profile of a typical Li-ion cell shows a nearly constant output voltage until the cell is near full discharge. (Image source: Eaton – Electronics Division)

Figure 1: The discharge cycle profile of a typical Li-ion cell shows a nearly constant output voltage until the cell is near full discharge. (Image source: Eaton – Electronics Division)

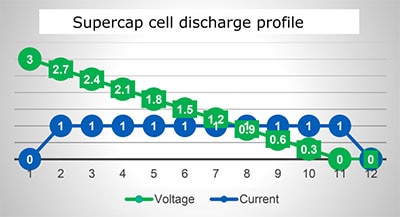

In contrast, EDLCs store energy using a physical process rather than a chemical reaction. These devices are symmetric with activated carbon electrodes at both the anode and cathode sides. Their charging and discharging are electrostatic processes with no chemical reaction, and their cycle life is practically unlimited. In contrast to batteries, their terminal voltage drops linearly as a function of the energy delivered (Figure 2).

Figure 2: In contrast to a Li-ion cell, a supercapacitor's output voltage declines steadily as it gives up stored charge. (Image source: Eaton – Electronics Division)

Figure 2: In contrast to a Li-ion cell, a supercapacitor's output voltage declines steadily as it gives up stored charge. (Image source: Eaton – Electronics Division)

EDLC technology is a relatively new development in the world of passive components. Even into the 1950s and 1960s, conventional wisdom was that a capacitor of even just one farad would be the size of a room. Instead, research into materials and surface technologies led to new structures and fabrication techniques, and eventually to what was dubbed the supercapacitor, providing tens and even hundreds of farads in a package comparable in size to other basic passives.

Topology options have tradeoffs

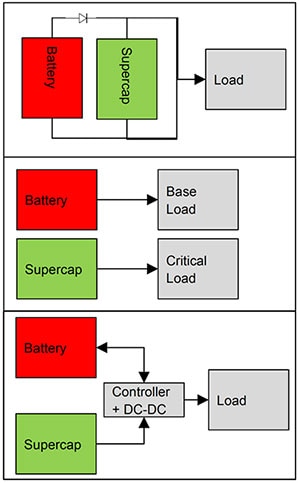

As a result of the basic design and performance differences between batteries and EDLCs, designers must decide whether to use just one energy storge device or combine both. If they choose to use a combination, they must then decide among various topologies, each with their respective tradeoffs and implications with regard to performance (Figure 3).

Figure 3: Designers can combine a supercapacitor and a battery in three common topologies: (from top) in parallel, as independent units, or combined via a controller/regulator. (Image source: Eaton – Electronics Division)

Figure 3: Designers can combine a supercapacitor and a battery in three common topologies: (from top) in parallel, as independent units, or combined via a controller/regulator. (Image source: Eaton – Electronics Division)

- The parallel approach is simplest, but the use of the supercapacitor is not optimal, and its output voltage is directly tied to the battery voltage.

- Using a battery and supercapacitor as independent units works best when there is a non-critical base load and a separate critical load as it provides independent power for each, but this approach does not offer the benefit of any sort of synergy between the separate units.

- The smart arrangement combines the capabilities of each energy source and maximizes both run time and cycle life time, but it requires additional management components such as a controller and DC-DC regulation between the two sources and the load; this topology is most commonly used with transportation-related power units.

When using topologies such as these, the choice of a battery and a supercapacitor is not an “either/or” decision. Designers can elect to use both, but using a battery and supercapacitor in combination requires the designer to face the challenge of finding the optimum balance between the differing characteristics of each.

The good news is that due to an innovative component, there’s no need to face an “and/or” dilemma when choosing whether to use batteries, supercapacitors, or both. A family of hybrid energy-storage components from Eaton – Electronics Division, combines the attributes of both in a single package, removing the need for compromise.

The case for hybrid supercaps

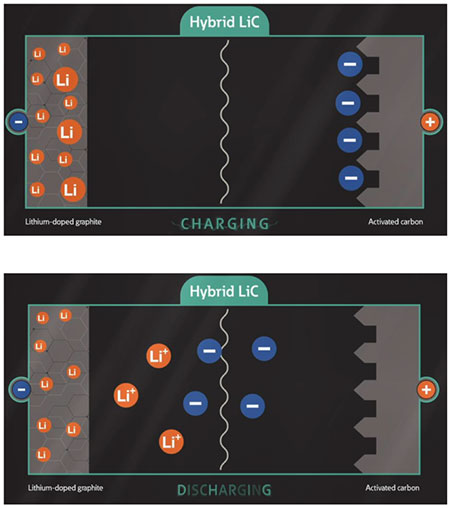

Hybrid supercapacitors combine the underlying structures of both batteries and supercapacitors in one physical unit. These hybrid components are not just a simple packaging of a distinct battery and supercapacitor pair in a common housing. Instead, they are energy sources that merge the chemistry of a battery with the physics of a supercapacitor in a single structure. As a result, these hybrid devices overcome the separate shortcomings of batteries and supercaps while providing clear benefits to the developer in meeting design requirements.

Hybrid supercapacitors are asymmetric devices comprising a Li-doped graphite anode and an activated carbon cathode. Although the charge movement is mainly done electrochemically, it is at a significantly lower depth compared to the Li-ion battery.

Among other attributes, this combination of technologies results in a very high cycle-life count (a minimum of 500,000 cycles is typical) and very fast responsiveness to high discharge rates (Figure 4).

Figure 4: The hybrid supercapacitor overcomes the charge/discharge cycle and rate limitations of a battery, among its other virtues. (Image source: Eaton – Electronics Division)

Figure 4: The hybrid supercapacitor overcomes the charge/discharge cycle and rate limitations of a battery, among its other virtues. (Image source: Eaton – Electronics Division)

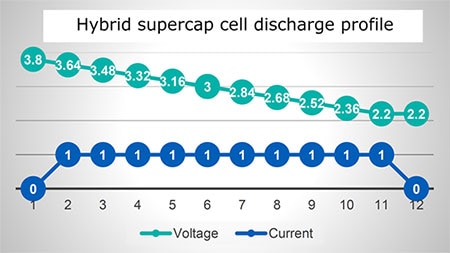

As an added benefit, no metal oxides are used and therefore these hybrid supercaps do not pose any risk of fire or thermal runaway. The output characteristics versus charge level are also compatible with the needs of low-voltage, low-power systems (Figure 5).

Figure 5: The output discharge profile of the hybrid supercapacitor lies between that of a battery and a standard supercapacitor. (Image source: Eaton – Electronics Division)

Figure 5: The output discharge profile of the hybrid supercapacitor lies between that of a battery and a standard supercapacitor. (Image source: Eaton – Electronics Division)

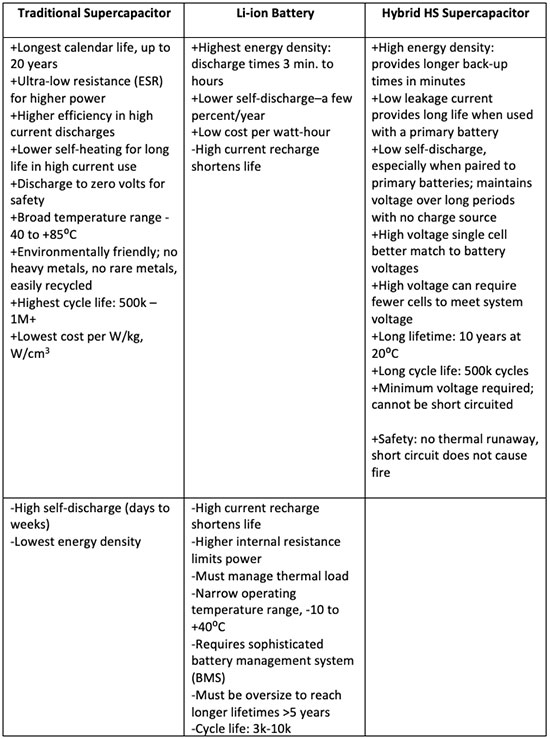

As with all components and design approaches, each energy storage solution offers tradeoffs in performance and capabilities. Table 1 shows the positive (“+”) and negative (“-”) attributes of these relative to each other, for typical cases.

Table 1: A comparison of the typical characteristics of a battery, a supercapacitor, and a hybrid supercapacitor shows the hybrid combines the best of both. (Table source: The author, using data from Eaton – Electronics Division)

Table 1: A comparison of the typical characteristics of a battery, a supercapacitor, and a hybrid supercapacitor shows the hybrid combines the best of both. (Table source: The author, using data from Eaton – Electronics Division)

Experienced engineers know that no single approach is perfect, and many times a single positive attribute of one of the available solutions is so vital that it overrides any of the other approaches. Therefore, system requirements will dictate the final solution.

Hybrid supercapacitors span farad/energy-capacity range

Unlike some specialized components which offer only a limited number of specifications, these hybrid supercapacitors are available covering a fairly broad performance range. For example, at the lower end of the range is the HS1016-3R8306-R, a 30 F unit in Eaton’s HS Series of cylindrical hybrid supercapacitor cells, measuring 18 mm long with a diameter of 10.5 mm (Figure 6).

Figure 6: The Eaton HS1016-3R8306-R is a 30 F unit in the HS Series of cylindrical hybrid supercapacitor cells. (Image source: Eaton – Electronics Division)

Figure 6: The Eaton HS1016-3R8306-R is a 30 F unit in the HS Series of cylindrical hybrid supercapacitor cells. (Image source: Eaton – Electronics Division)

The HS1016-3R8306-R has a 3.8 volt operating voltage, and its critical specification for initial ESR is a low 550 mΩ, resulting in fairly high power density—as much as eight times as that of a standard supercapacitor. It can provide 0.15 A continuous current (up to 2.7 A maximum) and has a stored energy capacity rating of 40 mWh. As with all members in the HS Series, it is UL recognized, greatly simplifying the overall product approval process.

For a larger capacity hybrid supercap in the same family, the HS1625-3R8227-R is a cylindrical 220 F device measuring 27 mm long by 16.5 mm in diameter, with an ESR of 100 mΩ delivering up to 1.1 A continuous and 15.3 A peak current. Its total energy storage capacity is 293 mWh.

With their combination of capacity, performance, and physical specifications, the Eaton hybrid supercapacitors are well-suited for providing standalone pulse power for wireless links in smart meters or in parallel with a battery. They are also a good fit for “ride-through” power during brief outages or brownouts in industrial process and programmable logic controllers, thus avoiding the resultant and often lengthy downtime that even a brief power problem can cause. Similarly, they can support volatile cache memory, servers, and multidisc RAID storge in data centers during such power interruptions.

Conclusion

For designers of IoT systems, hybrid supercapacitors are a good option for energy storage and power delivery due to their high energy densities, long cycle lifetimes, and higher working voltage. Built with these hybrid supercapacitors, designs can require fewer cells and smaller volume compared to standard supercapacitors, while also meeting temperature and lifetime requirements better than batteries alone. By removing difficult tradeoffs and compromise, these hybrid components enable design engineers to more easily meet challenging project objectives.

Recommended

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.