Quickly Negotiate Wearable Optical Signal Paths with a Multiparameter Monitor

Contributed By DigiKey's North American Editors

2021-06-02

Wearable health and fitness monitors use various techniques to collect a broad spectrum of movement, overall health, and sleep information. For designers, the problem is figuring out how to accommodate end-user demand for more functionality in these wearable monitors for pulse oximetry (SpO2), photoplethysmography (PPG), electrocardiogram (ECG), blood pressure, and respiration rate measurement. Each additional function only adds to the integration, power management, performance, weight, development time, and cost challenges facing designers.

For example, SpO2 solutions typically require complicated electronics with multiple integrated circuits (ICs) that create an optical path through the body using light-emitting diodes (LEDs), photosensors, transimpedance amplifiers (TIA), analog-to-digital converters (ADCs), and associated algorithms. ECGs require a sensitive, low-noise analog circuit with a front-end instrumentation amplifier and an ADC. These discrete systems also use additional hardware to reduce the effects of ambient light and manage electromagnetic interference (EMI). While these solutions work, they require significant pc board space and custom firmware, thereby increasing cost and extending development time. What’s required is a more complete and integrated solution that solves many of these design issues.

This article describes wearable physical entities and a multiparameter monitor comprising LED drivers, TIAs, a bandpass filter, an integrator, and an ADC. The article shows how to use a multiparameter monitor (Analog Devices’ ADPD4101) and associated development boards to simplify and accelerate the design process.

Analog front-end overview

Vital sign monitoring extends beyond the medical practice boundaries and into everyday life. Initially, health vital sign monitoring was under strict medical supervision in hospitals and clinics. Microelectronic processes and design advances provide cost reductions for wearable monitors, making telemedicine, sports, and fitness monitoring possible. With this expansion to wearable devices, health-related quality standards continue to satisfy the user’s high level of excellence expectations.

Vital sign monitoring involves measuring a series of physiological parameters that can indicate the health of an individual. For instance, an SpO2 measurement detects the percentage of blood oxygenation and heart rate. The appropriate sensors for SpO2 wearable devices are LEDs and photodiodes.

ECG and bioimpedance measurements determine heart rate, breathing, blood pressure, skin conductance, and body composition. The solutions for these vital signs must be compact, energy efficient, and reliable. Monitoring these critical signs requires optical, biopotential, and impedance measurements.

Optical vital sign signal paths

SpO2 measures the percentage of oxygen saturation in the blood and other vital signs. The blood oxygenation measurement uses an SpO2 technique which evaluates the LED’s light transmission through flesh at different optical frequencies. The SpO2 test can identify poor oxygenation, indicating the onset of diseases or disorders affecting the respiratory system. The data from the SpO2 measurement can also estimate the true arterial O2 saturation, and blood oxygen concentration (SaO2).

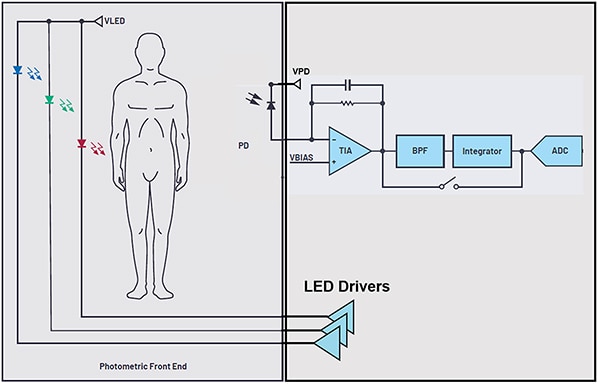

When making an SpO2 measurement, the optical system requires a toolbox of various LEDs and photodetectors. The typical signal chain for optical measurements has LEDs that generate several wavelengths that allow the overall identification of the relative blood oxygen level. A series of silicon photodiodes transform the received LED optical signal into a photocurrent. The amplification and ADC conversion of the photodiode’s current produces the needed resolution and accuracy (Figure 1).

Figure 1: The signal chain for the SpO2 test starts with LED light signals through the patient’s flesh. A photodiode captures the through the flesh signals, converting the LED light to a pico-ampere (pA) current signal. A TIA converts that current into a voltage and sends it to an ADC. (Image source: Analog Devices, modified by Bonnie Baker)

Figure 1: The signal chain for the SpO2 test starts with LED light signals through the patient’s flesh. A photodiode captures the through the flesh signals, converting the LED light to a pico-ampere (pA) current signal. A TIA converts that current into a voltage and sends it to an ADC. (Image source: Analog Devices, modified by Bonnie Baker)

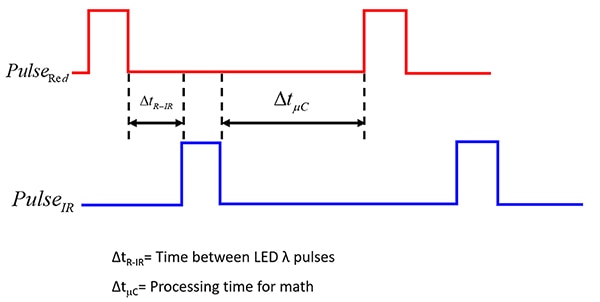

The SpO2 test uses 940 nanometer (nm) wavelength infrared (IR) and 660 nm red wavelength LEDs. With the 940 nm IR wavelength, oxygenated hemoglobin absorbs more of the IR light. Deoxygenated hemoglobin absorbs more of the 660 nm red wavelength light. The photodiode receives the non-absorbed light independently from both LEDs. However, these LEDs do not transmit light at the same time. There is a pulse sequence for the LEDs to ensure that crossover errors are negligible (Figure 2).

Figure 2: The SpO2 equipment’s timing of the 660 nm red LED (PulseRED) and the IR LED (PulseIR) ensures no light bleed over from each LED light signal. (Image source: Bonnie Baker)

Figure 2: The SpO2 equipment’s timing of the 660 nm red LED (PulseRED) and the IR LED (PulseIR) ensures no light bleed over from each LED light signal. (Image source: Bonnie Baker)

The perceived signals from the LEDs create AC and DC components. The AC component represents the pulsatile nature of arterial blood. The DC component is a constant that represents the light absorption due to the tissue, venous blood, and non-throbbing arterial blood. This component is the artery non-time-varying portion, which happens during the resting phase of the heart. Equation 1 shows the calculation of the SpO2 percentage:

![]() Equation 1

Equation 1

The discrete SpO2 measurement circuitry has six critical systems: LED driver amplifiers, TIAs, analog gain stage, ADC, digital-to-analog converter (DAC) to control the LED driver amplifier, and an analog voltage reference for the ADC and DAC.

The LED driver amplifiers need to cycle between two channels to ensure that the red and IR lights do not bleed into each other. The TIA takes the photodiode current and converts it to a voltage output. A gain amplifier increases the signal magnitude in preparation for the ADC input range at the TIA’s voltage output. Following the gain amplifier, an ADC digitizes the signal and sends it to a microcontroller or DSP. Lastly, the entire signal chain requires an analog voltage reference.

Biopotential and bioimpedance measurements

A biopotential is an electrical signal due to the body’s electrochemical activity. For example, a biopotential measurement can be an ECG. An exceptionally low heartbeat signal amplitude is 0.5 millivolts (mV) to 4 mV and has a frequency range from 0.05 Hertz (Hz) up to 40 Hz.

In the hospital or doctor’s office, the doctor monitors cardiac activity by attaching electrodes to the skin. Wet electrodes ensure good body contact, typically silver/silver-chloride (Ag/AgCl) pads. Individuals using wearable applications find that these electrodes are extremely uncomfortable and can easily dry out or start to irritate the skin.

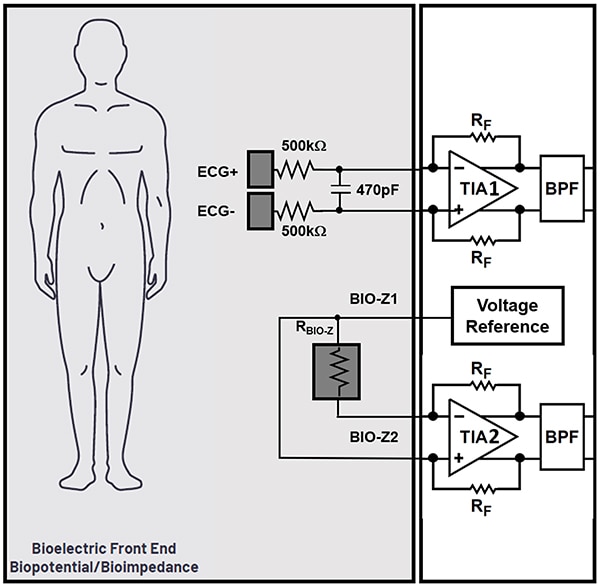

As an alternative, the wearable ECG circuit accumulates an electrical charge on a sensing capacitor. With an optimized time constant, calculated from the passive resistor-capacitor (RC) network, the charging process eliminates the variation on the skin-to-electrode contact impedance. In Figure 3, the ECG signal couples into an RC network and TIA1. This ECG circuit has innate immunity to variations in the skin-to-electrode contact impedance.

Figure 3: The ECG+ and ECG- pads are dry connections to the patient. These pads transmit the change in skin charge to the RC network. The BIO-Z1 and BIO-Z2 are connections through a flesh-patch resistor (RBIO-Z), and use TIA2 to measure the change in skin resistance in parallel with RBIO-Z. (Image source Analog Devices, modified by Bonnie Baker)

Figure 3: The ECG+ and ECG- pads are dry connections to the patient. These pads transmit the change in skin charge to the RC network. The BIO-Z1 and BIO-Z2 are connections through a flesh-patch resistor (RBIO-Z), and use TIA2 to measure the change in skin resistance in parallel with RBIO-Z. (Image source Analog Devices, modified by Bonnie Baker)

Bioimpedance is another measurement that provides useful physical information. Impedance measurements provide electrodermal activity information regarding the composition of the body and level of hydration. The second sensing circuit in Figure 3 measures skin resistance by using a pad resistance, RBIO-Z, in parallel with the skin resistance. This test does not require an LED signal. Skin resistance is approximately infinite unless the patient generates moisture or sweat underneath the pad. The generation of body sweat reduces the parallel skin resistance, increasing the current going into the inverting input of TIA2.

The wearable health fitness monitor presents a unique combination of physiological sensing challenges. Each additional requirement increases the circuit complexity and PC board real estate. As the number of health and fitness monitor options grows, so does the need for a highly integrated, complex, and compact IC.

The integrated multimodal sensor

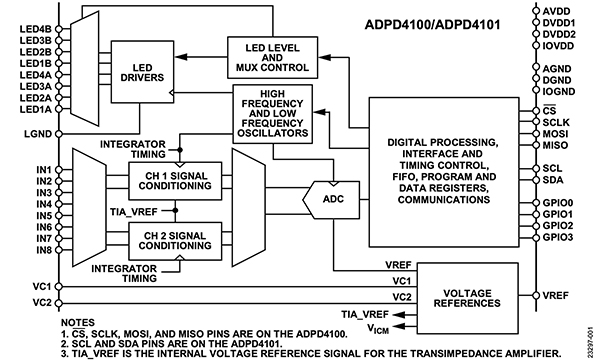

The ADPD4100 and ADPD4101 ICs are complete multimodal sensor front-ends that stimulate up to eight LEDs and measure the return signals with up to eight separate current inputs. Twelve timeslots are available, enabling twelve independent measurements per sampling period. The analog inputs can be driven single-ended or in differential pairs. The eight analog inputs are multiplexed into a single channel or two independent channels, allowing simultaneous sampling of two sensors. The only difference between these two products is that the ADPD4100 has an SPI interface and the ADPD4101 has an I2C interface (Figure 4).

Figure 4: The functional block diagram of the ADPD4100 and ADPD4101 illustrates the LED drive output channels and analog input channels. The input channels receive photodiode or capacitive current signals for conversion through the ADC. (Image source: Analog Devices)

Figure 4: The functional block diagram of the ADPD4100 and ADPD4101 illustrates the LED drive output channels and analog input channels. The input channels receive photodiode or capacitive current signals for conversion through the ADC. (Image source: Analog Devices)

In Figure 4, the digital processing timing control has twelve time slots available, enabling twelve separate measurements per sampling period. Along with external LEDs and photodiodes, the ADPD4100/ADPD4101's flexible architecture helps designers meet their wearable measurement needs by collecting biopotential and bioimpedance data. The ADPD4100 has a complete analog module with a digital SPI interface. The ADPD4101’s digital interface is I2C.

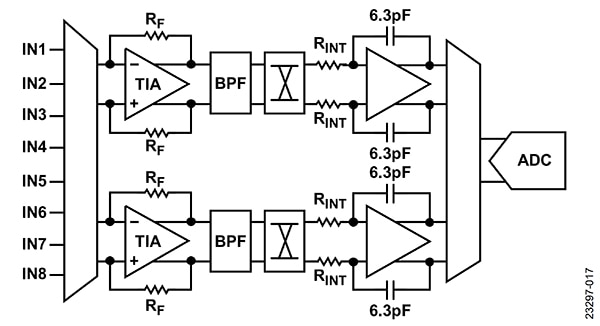

The ADPD4100/ADPD4101 analog signal paths consist of eight current inputs that are configurable as single-ended or differential pairs into one of two independent channels (Figure 5).

Figure 5: The analog signal path block diagram has eight analog input terminals and two TIAs. The bandpass filter (BPF) precedes the integrator that assists in increasing the ADC’s resolution. (Image source: Analog Devices)

Figure 5: The analog signal path block diagram has eight analog input terminals and two TIAs. The bandpass filter (BPF) precedes the integrator that assists in increasing the ADC’s resolution. (Image source: Analog Devices)

In Figure 5, the option of simultaneously sampling two sensors is available with the two TIA channels. Each channel can access a TIA with programmable gain (RF), a bandpass filter (BPF) with a high-pass corner at 100 kilohertz (kHz), a low-pass cutoff frequency of 390 kHz, and an integrator capable of integrating ±7.5 picocoulombs (pC) per sample. Each channel is time multiplexed into a 14-bit ADC. In Figure 5, RINT is the series resistor to the input of the integrator.

The ADPD4100/ADPD4101 solves many challenges designers face when working on wearable devices. The biomedical front-end meets all of the requirements with its high performance, dual-channel sensor input stage, stimuli channels, digital processing engine, and timing control. This multimodal sensor front-end generation has improved signal-to-noise specifications of 100 decibels (dB), and reduced power consumption (30 microwatts (µW)) for the entire system.

ADPD4101 evaluation board

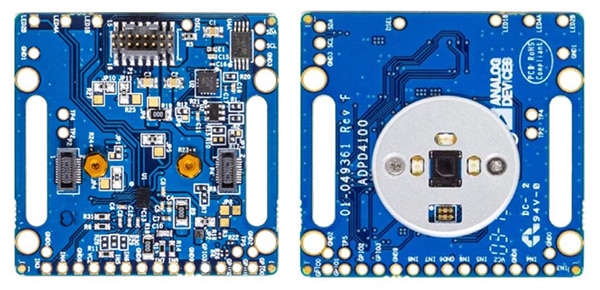

The EVAL-ADPD4100Z-PPG evaluation board (Figure 6) is valuable for designers considering the ADPD4100/ADPD4101 photometric front-end. The board implements a simple discrete optical design for vital signs monitoring applications, specifically wrist-based PPG.

Figure 6: The EVAL-ADPD4100Z-PPG board helps evaluate the ADPD4100/ADPD4101 for wrist-based PPG designs. The optical elements (right) comprise three green, one IR, and one red LED, as well as a photodiode. (Image source: Analog Devices)

Figure 6: The EVAL-ADPD4100Z-PPG board helps evaluate the ADPD4100/ADPD4101 for wrist-based PPG designs. The optical elements (right) comprise three green, one IR, and one red LED, as well as a photodiode. (Image source: Analog Devices)

The EVAL-ADPD4100Z-PPG has three green, one IR, and one red LED, all separately driven. There is also a single on-board photodiode, making this evaluation board ready for immediate operation.

An ADPD4101 reference design

A useful tool for connecting sensors to the ADPD4101 is the EVAL-CN0503-ARDZ reference design. This reference design does not speak to wearable monitors specifically but is useful to see how the CN0503 User Guide illustrates that the EVAL-CN0503-ARDZ uses the ADPD4101 to detect turbidity, pH, chemical composition, and other physical properties. The EVAL-CN0503-ARDZ reference design is a reconfigurable, multiparameter optical liquid platform that can perform colorimetry and fluorometry measurements (Figure 7).

Figure 7: Simplified schematic of the EVAL-CN0503-ARDZ optical liquid measurement platform. (Image source: Analog Devices)

Figure 7: Simplified schematic of the EVAL-CN0503-ARDZ optical liquid measurement platform. (Image source: Analog Devices)

The EVAL-CN0503-ARDZ, in combination with the EVAL-ADICUP3029 development board, has four configurable optical paths (Figure 8). The two outer paths also include perpendicular photodiodes and filter receptacles for fluorescence and scattering measurements. Each path has an excitation LED, condenser lens, beam splitter, reference photodiode, and transmit photodiode.

Figure 8: Fully assembled EVAL-CN503-ARDZ on the top and EVAL-AIDCUP3029 on the bottom. (Image source: Analog Devices)

Figure 8: Fully assembled EVAL-CN503-ARDZ on the top and EVAL-AIDCUP3029 on the bottom. (Image source: Analog Devices)

This optical setup, in conjunction with the CN0503-Device Driver and Wavetool Evaluation Software, provides a path to comprehensive optical liquid analysis.

Conclusion

Designers are constantly asked to add more functionality to wearable monitors. This further complicates and slows the design process, adds component cost, and increases power consumption. A more integrated approach for health monitoring is required.

As shown, the combination of LEDs, photodetectors, an ADC signal path, and twelve timed signal paths provided by the ADPD4101 from Analog Devices creates a high-precision, robust sensing system for wearable medical and recreational devices. With the ADPD4101’s multiple LED and analog channels and superior timing algorithms, the device provides an ideal solution for wearable SpO2, heart ECG, and skin resistance measurements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.